Dried Fish: A Concentrated Source of Protein and Minerals

An essential ingredient in Bengali cuisine is dried fish, or “shutki” as it is known locally. The rich cultural and culinary traditions of the Bengali population contribute to its significance. Because of its intense taste, dry fish is widely valued. A tiny quantity of dried fish may provide a strong, savory flavor to a wide variety of foods, enhancing the dish’s overall flavor profile.

There are around 40 different types of fish which are very popular dried fish among the traders and buyers. Among those Loitya (Bombay duck), Chhuri (Ribbonfish), Chanda (Elongate Glassy Perchlet), Coral fish, Maitya (Sardine), Poa (Pama Croaker), small and big Shrimp, Chapa Hari, Soma-matya are mostly sold as a dried fish.

Figure 1: Various Types of Dried Fish

In Bangladesh, fish drying is done in a few specific coastal locations and inland depressions where there aren’t any modern facilities for preservation or efficient transportation. Dublar Char in the Sundarbans, St. Martin’s Island, Rangabali, Sonadia Island, Moheshkhali, Cox’s Bazar, Ibrahimpur, and Joshomantapur are a few of the significant locations.

Pressed dried fish, or Chapa Shutki, is made in the districts of Kishoreganj, Mymensingh, Narsingdi, Sylhet, Comilla, and Narayanganj by fermenting tiny Punti fish. Large-scale Chapa Shutki is produced at Madhabdi in Narsingdi, Kuliarchar and Lalpur of Kishoreganj.

Fish are thought to contribute around one-sixth of all protein in the planet. In certain underdeveloped countries and areas that depend considerably on seafood, that percentage is noticeably higher.

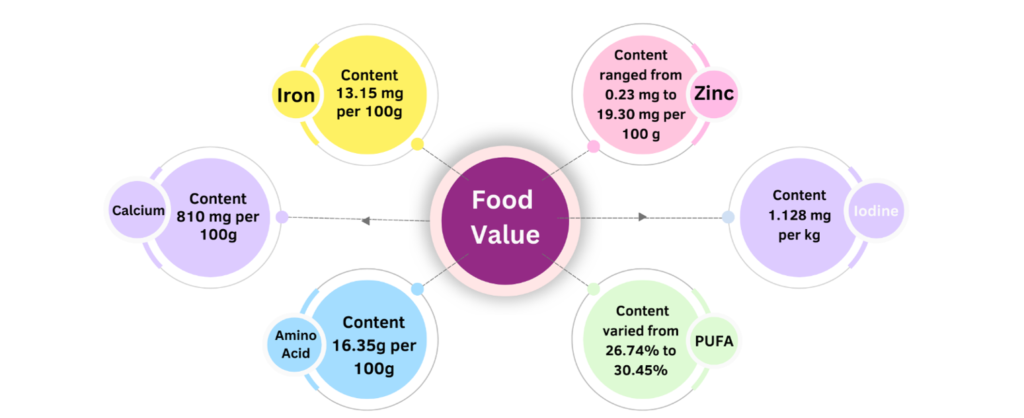

A review of dried fish’s nutritional value revealed that, “Dried fish is a good source of high-quality protein because its nutrient density is three to four times higher than that of fresh fish. According to the data, the highest amount of essential amino acids was found among three species namely: Churi, Coral, and Rupchanda [1]. The dried fish’s amino acid composition reveals that it contains all essential amino acids, including lysine, which is missing from terrestrial animal proteins, and sulfur-containing amino acids like methionine, which are found in insufficient amounts in plant proteins.

Moreover, docosahexaenoic acid and eicosapentaenoic acid were prominent in dried fish [2]. According to the data, the three most common fatty acids were palmitic acid, palmitoleic acid, and linoleic acid with an amount of 47.15 g, 11.53 g, and 11.35 g per 100 g of dry fish, respectively.

Data show that the average folate, thiamine, riboflavin, and vitamin B6 content of the dry fish was 22 µg, 0.16 mg, 0.68 mg, and 0.43 mg per 100 g of dry fish, respectively.

The content of minerals such as iron, zinc, calcium, phosphorus, magnesium, sodium, potassium, manganese, and copper was assessed in 23.76%. The bioavailability of iron is extent in the dried fish. The highest amount of zinc was identified in dried Tengra (Mystus tengra).

Generally, fish contains very little carbohydrate, while the moisture content is very high. In most fish species, moisture content is between 60-80% (Pearson & Cox, 1976). Due to high content of moisture present in raw fish it’s spoils quickly if it cannot be preserved in a particular manner. Food preservation techniques like drying work by eliminating the moisture from the food, which stops microbes from growing. Drying efficiently stops bacteria, yeasts, and molds from surviving in the food. Inhibiting enzymatic activity also prevents the biological response from proceeding more quickly

There are two basic mechanisms involved in the drying process; the migration of moisture from the interior of an individual cell to the surface, and the evaporation of moisture from the surface to the surrounding air. The rate of drying is influences by the moisture content and the temperature of the fish, also the temperature, the relative humidity and the velocity of the air in contact with the fish.

The basic concept behind raw fish to dry fish processing is simple. Sundry the fish so that the water content from the flesh evaporates leaving the muscle enzyme in an inactive phase, which could otherwise prompt rotting. The natural air currents take the evaporated water with them. The sun dry process is inexpensive and efficient; the fisherman and his family can handle the tasks, and the finished product can be readily transported to markets.

The other method of drying fish is mechanical process that involves the use of mechanical equipment to remove moisture from fish. This method is commonly employed in the fish processing industry to extend the shelf life of fish products and reduce the risk of spoilage. Some common methods are Cabinet drier, Kiln Drier, Tunnel Drier, Vacuum Shelf Drier, Freeze Drier etc.

The problem of traditional drying methods is the chance of infestation by insects and other microorganisms. Fishermen used to spray hazardous chemicals to prevent it from happening.

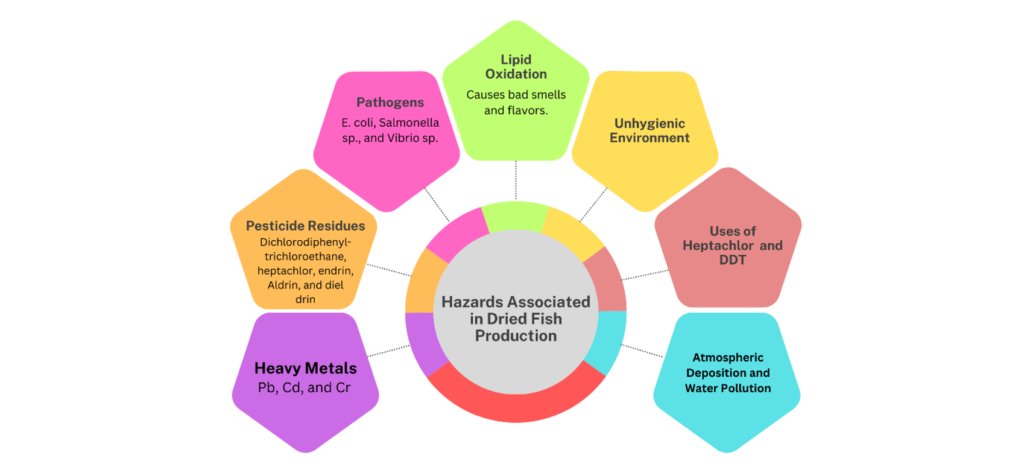

An analyst reported that several dried fishes were contaminated with a high content of heavy metals (for example, Pb, Cd, and Cr), pesticide residue (dichloro-diphenyl-trichloro-ethane, heptachlor, endrin, Aldrin, and diel drin) and other harmful chemicals such as DDT and heptachlor [3] [4].

Additionally, they stated that the bad smells and flavors in certain dried fish from Bangladesh were caused by lipid oxidation. Sun-based drying affects polyunsaturated lipids and can promote lipid oxidation, which can reduce the nutritive value and functional quality and raise consumer health risks [5].

These pesticides are used to protect fish from insect infestation; however, they are associated with serious health problems, including cancer and non-allergic reactions, and environmental hazards [6].

Considering the situation, the following recommendations can be highlighted to prevent the use of hazardous chemicals or insecticides during dry fish production:

(i) Organochlorine compounds have been outlawed in several nations, because of possible health risks. As a result, the Bangladeshi government should enforce the most recent pesticide laws and regulations regarding fisheries goods.

(ii) Researching and implementing safe insect control strategies is important. Red pepper and turmeric (separately or mixed) have insect- and bacteria-repealing characteristics and thus can be used in fish drying. Evidence shows that the pretreatment of fish with 10–12% salt for 10–12 h can reduce infestation [7].

(iii) Developing improved and cost-effective methods of fish drying, designing effective packaging and storage facilities beside setting up public health awareness campaigns for dry fish producers.

References

- Nutritional Value of Dry Fish in Bangladesh and Its Potential Contribution to Addressing Malnutrition: A Narrative Review. by Md. Hasan Al Banna.

- Rasul, M.G.; Kabir, I.E.; Yuan, C.; Shah, A.K.M.A. Research Article effects of drying methods on physico-chemical, microbiological and sensory properties of torpedo scad (Megalaspis cordyla). J. Microbiol. Biotechnol. Food Sci. 2021, 10, e2796. [Google Scholar]

- Rasul, M.G.; Yuan, C.; Shah, A.K.M.A. Chemical and Microbiological Hazards of Dried Fishes in Bangladesh: A Food Safety Concern. Food Nutr. Sci. 2020, 11, 523–539. [Google Scholar]

- Hasan, M.N.; Islam, H.M.R.; Akter, R.; Mahmud, Y.; Ahmed, K.K.U.; Siddiquee, S. Determination of Dichlorodiphenyltrichloroethane Residues Levels in Commercial Marine Dry Fish from Different Regions of Bangladesh. Annu. Res. Rev. Biol. 2014, 4, 2722–2729. [Google Scholar] [CrossRef]

- Siddhnath; Ranjan, A.; Mohanty, B.P.; Saklani, P.; Dora, K.C.; Chowdhury, S. Dry Fish and Its Contribution towards Food and Nutritional Security. Food Rev. Int. 2020, 38, 508–536. [Google Scholar] [CrossRef]

- Rasul, M.G.; Majumdar, B.C.; Afrin, F.; Jahan, M.; Yuan, C.; Shah, A.K.M.A. Physico-Chemical, Microbiological and Sensory Changes in Sun-Dried Trichogaster Fasciata During Storage. Turk. J. Agric. Sci. Technol. 2019, 7, 1568–1574. [Google Scholar] [CrossRef]

- Siddhnath; Ranjan, A.; Mohanty, B.P.; Saklani, P.; Dora, K.C.; Chowdhury, S. Dry Fish and Its Contribution towards Food and Nutritional Security. Food Rev. Int. 2020, 38, 508–536. [Google Scholar] [CrossRef]